AGI Denim’s Strategic Expansion: Advancing Global Innovation, Sustainability, and Production Capacity

AGI Denim is strategically embarking on a significant expansion of its operational capabilities, directly addressing the escalating global demand for high-quality, sustainable denim products. This comprehensive initiative involves substantial investments across key areas, including state-of-the-art technology, enhanced sustainability practices, and increased production capacity throughout its entire value chain.

This roadmap provides a detailed overview of the company’s major developments, highlighting the commitment to operational excellence and environmental stewardship.

Phase I: Strengthening Core Manufacturing Capabilities

This initial phase focuses on enhancing the foundational elements of AGI Denim’s production process, from raw material handling to fabric creation.

Fabric Mill Expansion Underway: Scaling Production to Meet Demand

AGI Denim currently maintains an annual production capacity of 60 million yards of denim fabric, serving a diverse portfolio of international brands. To proactively meet the accelerating market demand, the company is implementing a strategic, multi-phased expansion of its fabric mill infrastructure.

This expansion will culminate in a total increase of 18 million yards by the second quarter of 2025, significantly bolstering our capability to fulfill growing global partner requirements and strengthen our market position.

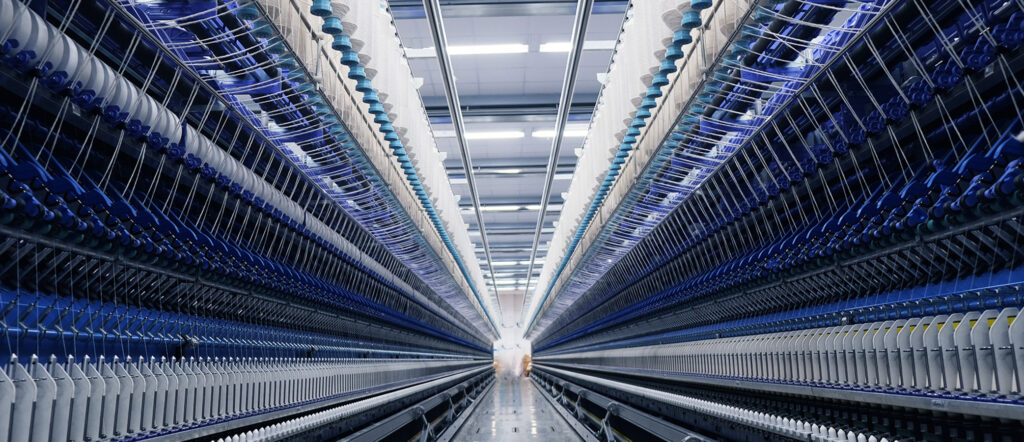

Advancements in Spinning Operations: Enhancing Yarn Quality and Efficiency

AGI Denim has achieved remarkable progress through the integration of advanced spinning technology, resulting in a notable 20% improvement in yarn production efficiency. This efficiency gain has directly translated into an 8% increase in overall annual yarn output.

Furthermore, the installation of modern Trutzschler carding machines ensures not only consistent and superior yarn quality, but also offers optimized user-friendly functionality for our operational teams. These advancements underscore our commitment to vertical integration and control over the raw material quality.

Innovations in Dyeing Technology: Expanding Capabilities with Sustainable Solutions

The adoption of a state-of-the-art dyeing range represents a significant leap forward in AGI Denim’s dyeing capabilities. This cutting-edge system has not only expanded the range of dyeing possibilities but has also enhanced color consistency across production batches, which is a critical factor for brand partners.

With an extended dyeing range, the Smartec line delivers vibrant, high-quality shades across various applications, including topping, bottoming, and pure indigo. Designed with sustainability in mind, it significantly reduces water, energy, and chemical consumption, optimizing resource efficiency while minimizing environmental impact.

The system’s ability to handle multiple dyeing processes simultaneously ensures smooth, high-speed operations with minimal downtime, resulting in both cost and time savings without compromising quality.

Upgrading Weaving Capabilities: Introducing Next-Generation Loom Technology

AGI Denim has undertaken a substantial upgrade of its weaving line with the implementation of the latest Picanol Ultimax Rapier Looms. This marks the first deployment of this advanced weaving technology in Pakistan, reinforcing AGI Denim’s leadership in adopting cutting-edge manufacturing solutions. The previous generation of looms operated at 650 RPM (Revolutions Per Minute), whereas the new Picanol Ultimax looms achieve speeds of up to 700 RPM, significantly boosting productivity.

These advanced looms are also engineered to enhance energy efficiency, minimize material waste during the weaving process, and consistently deliver exceptionally high-quality fabric. This upgrade underscores our unwavering commitment to operational excellence and product superiority.

Phase II: Refinement, Sustainability, and Diversification

This phase highlights AGI Denim’s dedication to sustainable practices, enhanced product finishing, and strategic diversification beyond traditional denim.

Enhancements in Finishing Processes: Precision and Efficiency in Fabric Treatment

The introduction of the new Cibitex Sanforizing Machine represents a pivotal upgrade to AGI Denim’s fabric finishing operations. This state-of-the-art system provides improved overall finishing quality, integrating advanced washing capabilities directly into the process. Furthermore, it offers real-time performance monitoring, allowing for immediate adjustments and optimized results.

These comprehensive enhancements contribute significantly to superior product quality, while simultaneously achieving notable reductions in water consumption and increasing overall process efficiency, reflecting our twin goals of quality and sustainability.

Proactive Environmental Stewardship: Investing in a Greener Future

Sustainability remains a paramount and deeply integrated focus for AGI Denim across all operations. In a major step towards environmental responsibility, a new water recycling plant is currently being implemented, with the capacity to recover up to 0.5 million gallons of water daily.

This initiative will significantly reduce our operational water footprint. Complementing this, the company is actively investing in expanding its renewable energy portfolio through increased solar capacity and the integration of a biomass boiler. These collective efforts are designed to further lower our environmental impact and support a more circular economy.

Commitment to Regenerative Cotton Farming: Cultivating Sustainable Raw Materials

AGI Denim is actively engaged in promoting sustainable agriculture through its regenerative cotton project, a long-term commitment to environmentally sound sourcing. This impactful initiative currently encompasses 7,000 acres of farmland, involving 1,300 dedicated farmers who collectively produce 15,000 bales of cotton annually. This specific project is projected to yield approximately 4 million yards of fabric made from regeneratively grown cotton. Crucially, we have achieved the regenagri certification in the first quarter of 2025, underscoring our profound dedication to environmentally responsible and traceable sourcing practices.

Diversification with Apparel Park Development: Expanding Product Horizons

AGI Denim’s new Apparel Park signifies a major strategic diversification into non-denim apparel categories. This purpose-built facility is equipped with advanced apparel manufacturing technologies, enabling us to broaden our product range beyond traditional denim. Supported by a substantial $20 million investment, this expansion facilitates the efficient production of high-quality chinos, cargo pants, and dress trousers.

This investment is not only diversifying the company’s product offering, but also expands our market reach and strengthens our position as a versatile textile solutions provider.

Phase III: Sustainable Finishing

This final phase details further advancements in sustainable garment finishing and AGI Denim’s overarching vision.

Expanding Laundry Capacity for Sustainable Finishing: Innovations in Garment Treatment

By the first quarter of 2026, AGI Denim is set to significantly increase its laundry capacity by an additional 20,000 garments per day. This expansion will be facilitated by the integration of advanced laser and Tonello machines, representing the forefront of sustainable garment finishing technology. The upgraded facility is meticulously designed to implement 80% dry processes, drastically reducing water usage, and will strategically utilize 50% recycled water for the remaining wet processes. This commitment to sustainable laundry practices further reinforces AGI Denim’s leadership in eco-conscious manufacturing.

The Road Ahead: Innovation, Excellence, and Responsibility

AGI Denim’s comprehensive expansion roadmap unequivocally demonstrates a clear and robust commitment to continuous innovation, operational excellence, and profound environmental responsibility. Through these strategic and integrated investments across its entire manufacturing ecosystem, from the initial fiber procurement and yarn spinning to fabric weaving, dyeing, finishing, and ultimately, finished garment production, the company is exceptionally well-positioned.

We aim to not only effectively meet the evolving requirements of our global partners, but also to establish industry benchmarks in sustainable and high-quality denim manufacturing for years to come.