Rota Spray is a revolutionary indigo spray dyeing production procedure, with reduced environmental impact. The breakthrough technology was created by a collaboration between DyStar and RotaSpray.

First introduced in 2015, it was refined by the two companies to make it available for bulk production in important denim markets.

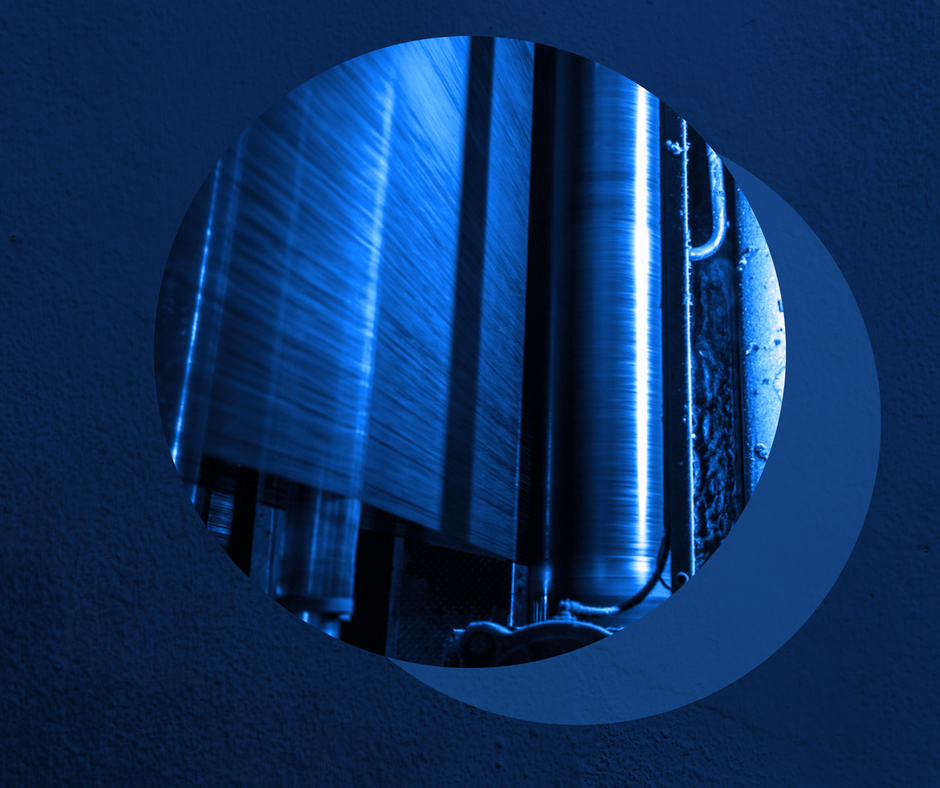

This new method combines special dyes with roto spray technology: specifically DyStar Indigo Vat 40% Solution, Sera Con C-RDA organic reducing agent and patented RotoDyer and RotoCoater spraying technology. It is a revolutionary development for the environment, because it eliminates the need to run yarns through large vats of dyes repeatedly, and to prepare and discard huge amounts of chemicals and dyes.

Founded in 2013, RotaSpray manufactures rotating atomizers for tailor-made conceptions in dyeing and finishing of warp yarn, fabric and nonwoven.

The DyStar Group is a leading dyestuff and chemical manufacturer and solution provider, offering its global customers a portfolio of colorants, specialty chemicals, and services.

Although rotary atomizers have been in the textile industry for several decades, they were mainly used for rewetting textiles.

But with recent global interest in sustainable solutions and cost pressures, the demand for such research increased.

Rota Spray technology boasts important ECO certificates, and offers flexibility for dyeing small lot sizes, lower effluent discharge impact on yarn in the dyeing process. Most importantly, reduced water usage.

AGI Denim is proud to be the first denim supplier equipped with the RotaSpray Dyeing Technology in Pakistan.