Close

55 million yards of

fabric produced every year

25 million garments produced

every year

34 state of the art high

speed lasers

SGS approved in-house

laboratories

Production spread out over

17 specialized facilities

in Karachi

Experts from the US,

Sri Lanka, Spain,

Turkey and Italy

Designed according to the industry 4.0 principles, our state-of-the-art new LEED-certified spinning mill has the capacity to produce 22 million kg of yarn annually.

In keeping with a zero-waste focus, an automated shredding unit will convert post-consumer waste into recycled fibre that will replace a portion of the conventional cotton in the spinning process.

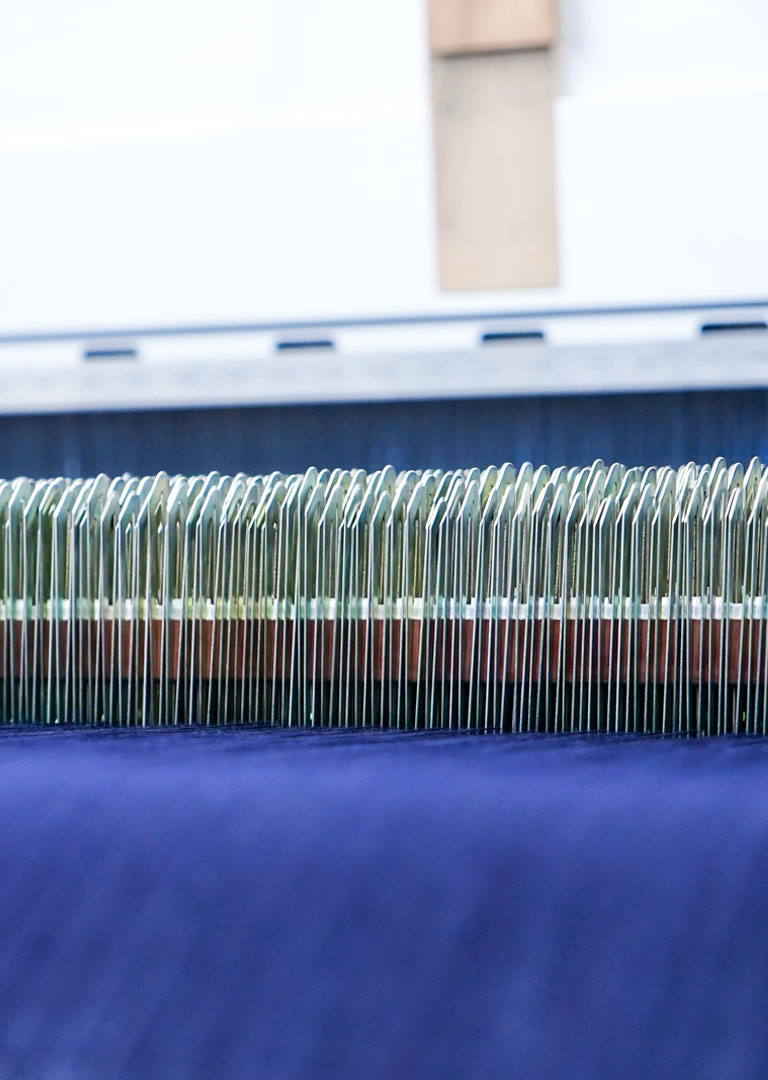

From weaving, dyeing to finishing— our mills follow an efficient and environmentally sensitive process. Weaving facilities include 300 state of the art European looms consisting of Rapier, Airjet and Dobby Technology. We have developed new washing and dyeing techniques to offer our customers a more sustainable way of treating fabrics. Our Dyeing Ranges include over 300 looms, 4 dyeing machines (2 Rope and 2 Slashers), Sustainable Dyeing, Cadira, and our breakthrough Zero Waste Water Dyeing.

Our diverse fabric finishing is equipped with Mercerizing, coating, bleaching, and over-dyeing capabilities.

With control over raw materials, yarn manufacturing, and subsequent processes, we offer a product that doesn’t compromise on fabric performance, shade consistency or finish.

It all starts with our Fabric R&D Studio, where the new fabric is developed, the latest trends are uncovered, environmentally sustainable practices are researched, and more efficient production methods are sought out, all of which lead us to bring something new and unique to the denim market.

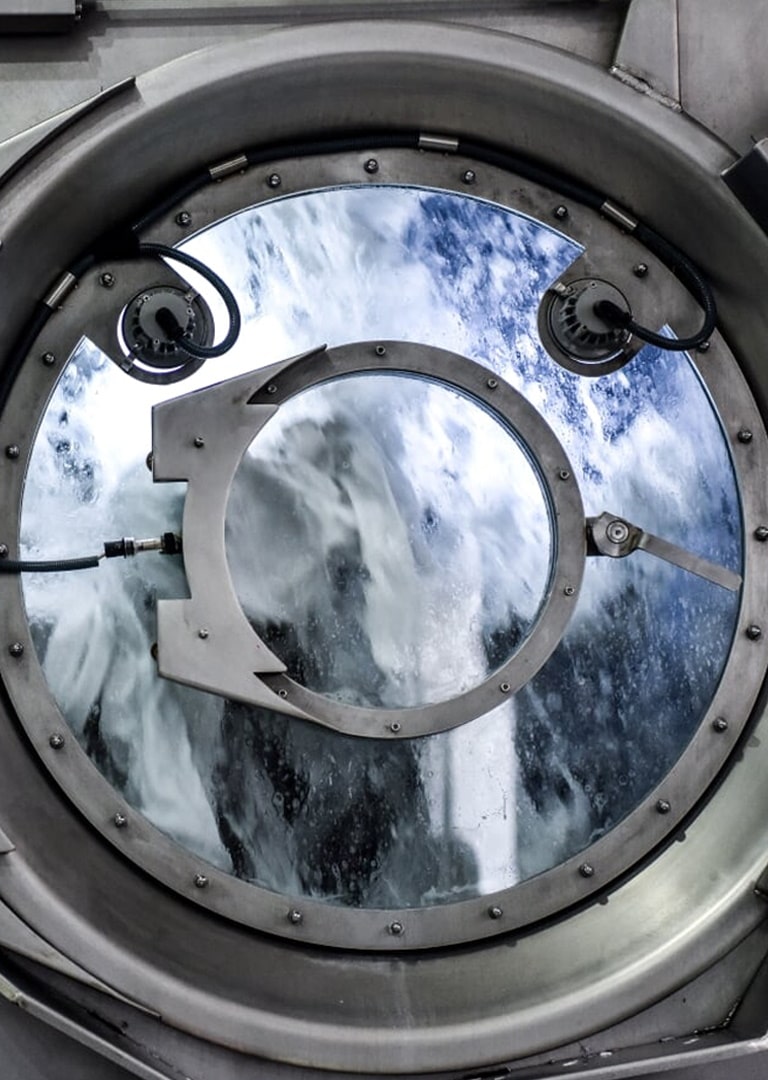

The commitment to move towards premium quality and innovative designs is facilitated by our laundry; a modern plant equipped with European washing machines. Our stitching facilities are equipped with high-tech machinery to maintain top quality.

High-speed laser machines add further value to our product and move us closer to an environmentally friendly manufacturing process. Our services are specialized for each individual customer so that the facility is run as an extension of the brand’s values and quality parameters.